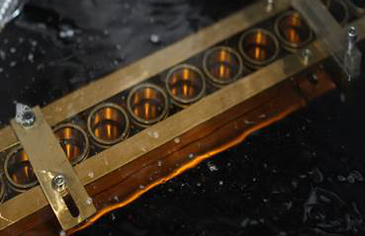

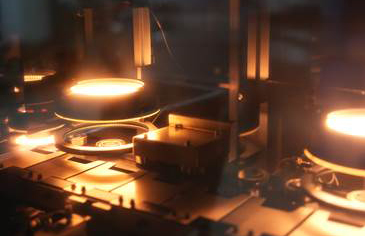

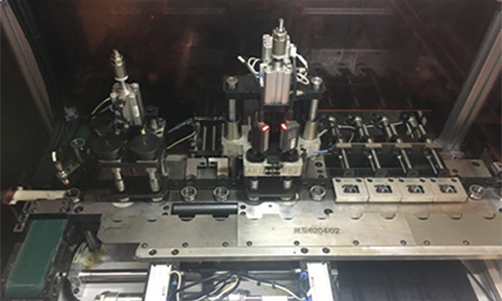

The enterprise adopts automated assembly line production, introduces advanced domestic automatic CNC high-precision grinding machines, end surface automatic ultra precision machines, and completes sets of automatic assembly equipment, which saves labor costs to the greatest extent and increases production volume.

In terms of technology, from the most primitive manual vibration measurement to fully automatic vibration measurement. Adhere to the goal of Z3, V3, Z4, V4 and higher requirements, strictly standardize operations, and improve quality assurance. Key items such as inner and outer diameter dimensions, vibration, and oil content have achieved 100% full inspection online. The assembly production line is equipped with multiple error prevention and control points throughout the entire process, ensuring that product quality meets customer expectations.

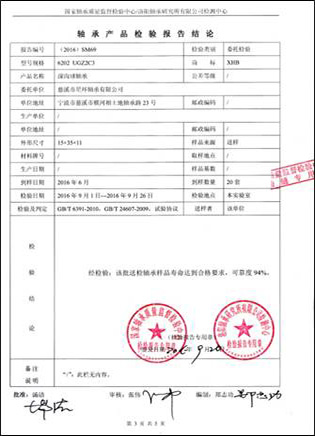

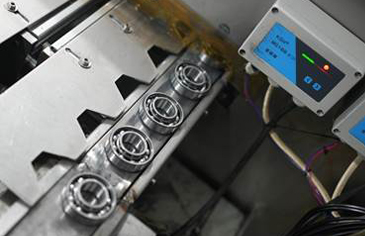

Output production line

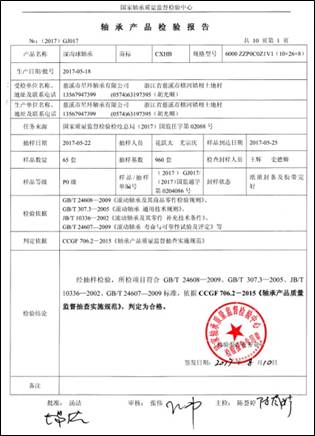

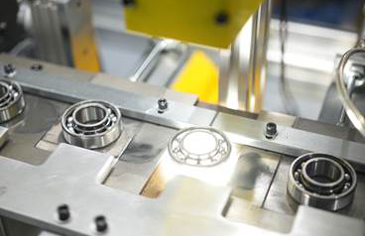

Grinding line

Full-automatic assembly line

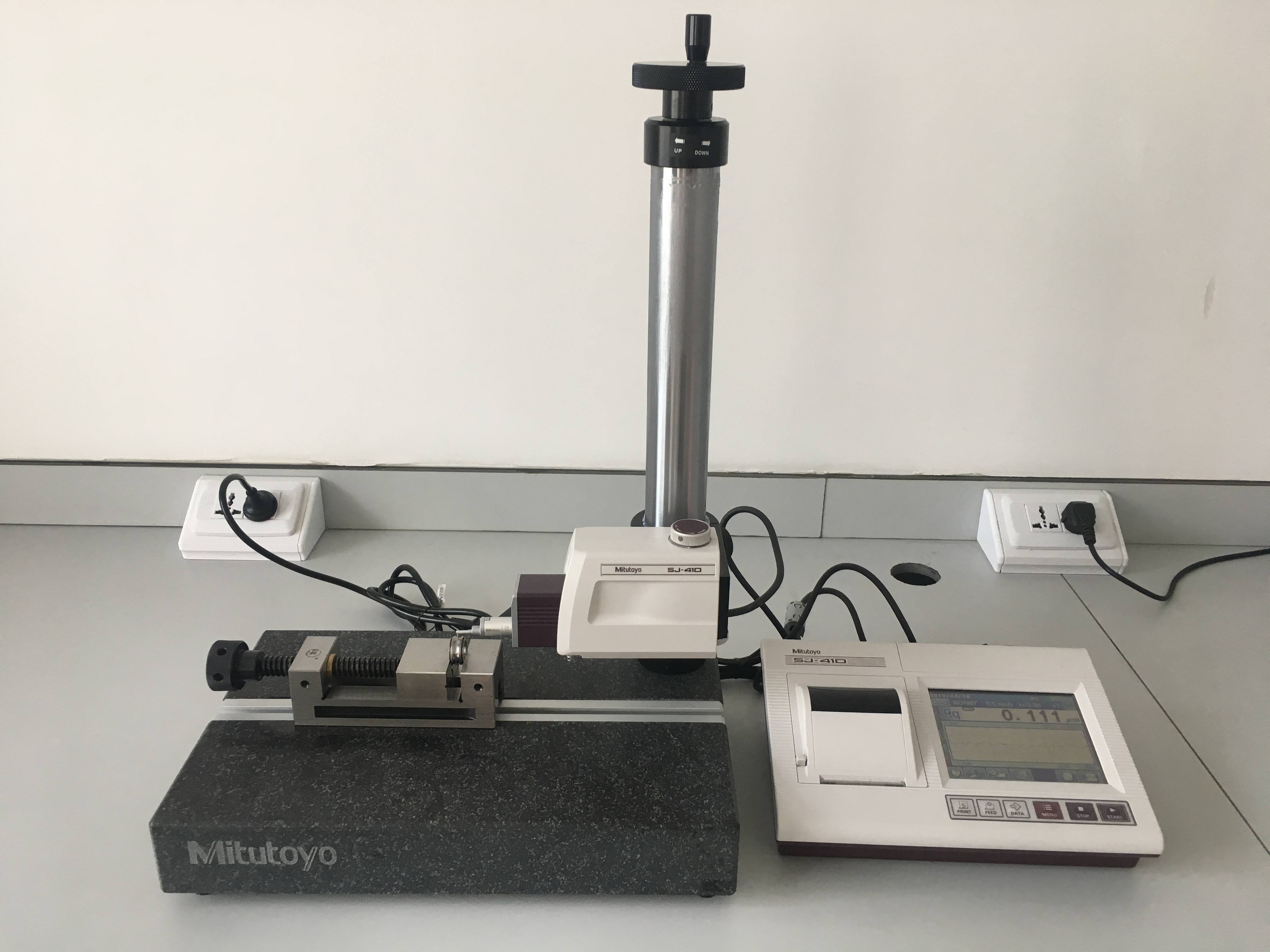

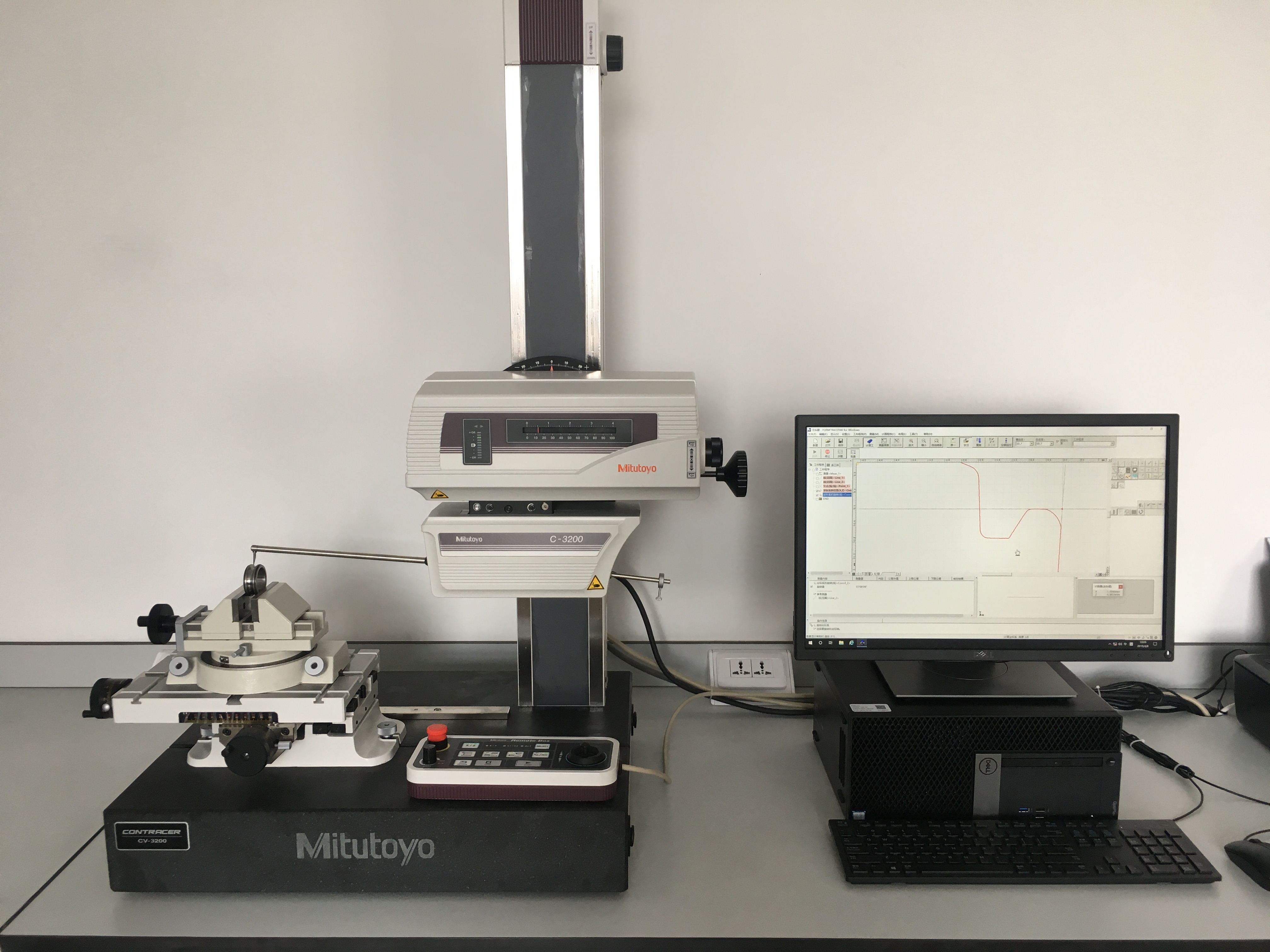

Enterprise adopts automatic assembly line production, introduces China’s advanced automatic NC high precision grinding machine, head-face automatic super-finishing machine and a set of automatic assembly equipment. Testing equipment is equipped with a complete testing system composed of Y9025G roundness measuring equipment, Mitutoyo roughness instrument, Mitutoyo contourgraph, metalloscope, impact detector, sealing rubber tensile shredder, SO910 vibration meter and BVT. In the aspect of processing technique, the company sticks to Z3, V3, Z4 and V4 and higher requirement strictly standardizes operation and improves quality guarantee. It implements 100% full inspection of key programs such as outside and inside diameter, vibration and amount of grease, equips with multiple fail-safe rejection reference point in the whole process of assembling line and makes sure that product quality meeting customers’ expectation.

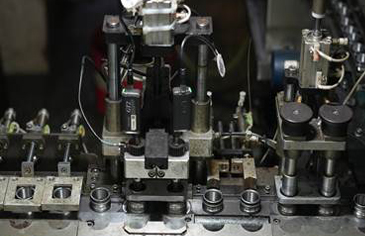

In order to ensure that the product quality of bearings is consistent with relevant standard requirements in the process of production, we have specially set up “Testing Center” carrying out following procedures:

1. Production, check and management of whole-process standard parts

2. Measurement and analysis of rings’ microstructure and hardness

3. Projection measurement and analysis of shape structure of rings and seals

4. Measurement and analysis of rings’ curvature shape

5. Measurement and analysis of burn of rings and steel balls

6. Measurement and analysis of cleanliness of rings and finished bearings

7. Measurement and analysis of seals’ properties such as rubber stretching, tearing, abrasion, hardness and vulcanization

8. Measurement and analysis of speed and acceleration value of finished bearings

9. Performance test of used oil products during production

Parts’ roughness test

Bearing parts’ shape and contour test

Metallographic test

Image test

Acid burn test

Rubber stretching and tearing test

All bearing parts are from CITIC Taifu Group. It is the highest quality GCr15 bearing steel in China and recognized in the industry. It is produced strictly according to national standards, and the ring undergoes 100% inspection to prevent defective raw materials such as cracks, warping, and interlayers from entering the subsequent process.

The role of tooling and abrasives in production is comparable to that of equipment and instruments. In order to purchase these key materials, we have set our sights on the world, searching for and selecting high-quality materials worldwide, so that our product quality can reach the advanced world level.

All steel balls are made of G10Z4 steel balls produced by top domestic steel ball manufacturers; In our company's incoming material inspection process, in addition to inspecting conventional items such as size, appearance, and abnormal sounds, we also control items such as burns, metallographic structure, hardness, and accept them according to zero defect standards. The purpose is to ensure the service life of finished bearings.

During the incoming inspection process, in addition to trial installation and routine dimensional item testing, the determination of the detachment force after riveting of the retainer is also added to avoid reducing the bearing life due to retainer failure during bearing use.