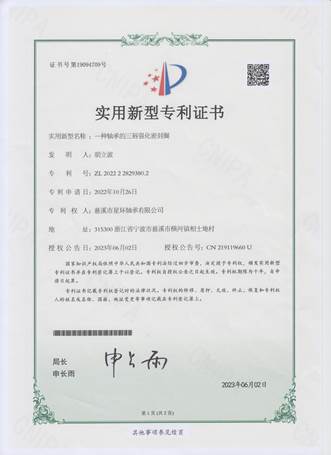

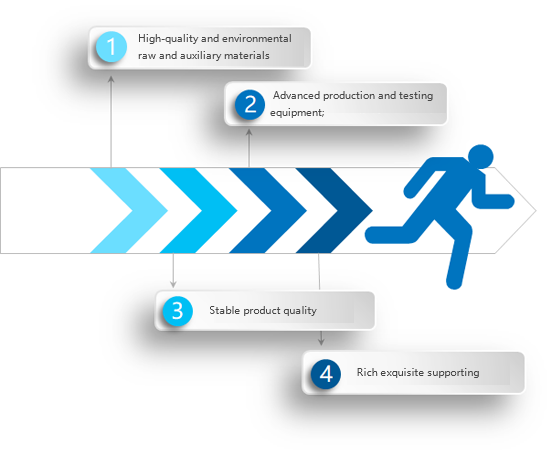

The company applies world’s high quality raw and auxiliary materials, equips domestic leading production equipment and realizes comprehensive processed manufacturing. At the same time, we own specialized testing center for unremitting precision test of bearings’ service life and effect. We also control product quality in accordance with the management system of IATF16949:2016. All raw materials conform to requirements of EU RoHS and REACH. We have been making great efforts in protecting natural resources and relieving the environmental burden.

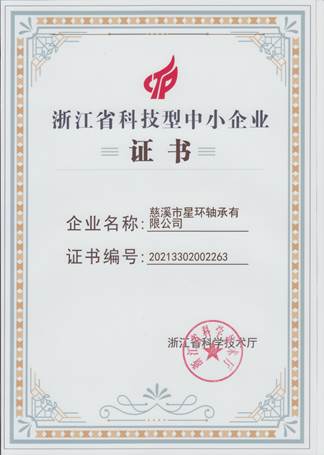

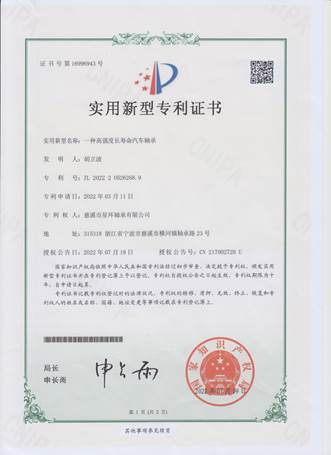

Under great quality system and process control, Xinghuan Bearing not only guarantees its product quality, but also has prominent quality stability. In current production field of ball bearings in China, Xinghuan Bearing has played a significant role. We aims to become an exquisite bearing manufacturer and to meet motor users and automobile bearing users’ requirement for high quality bearings.

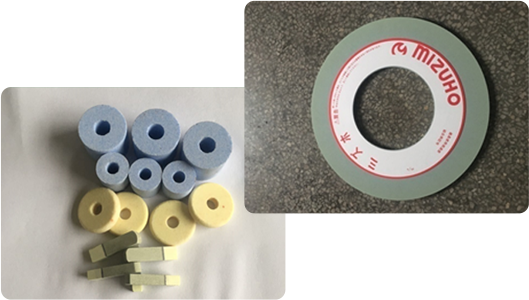

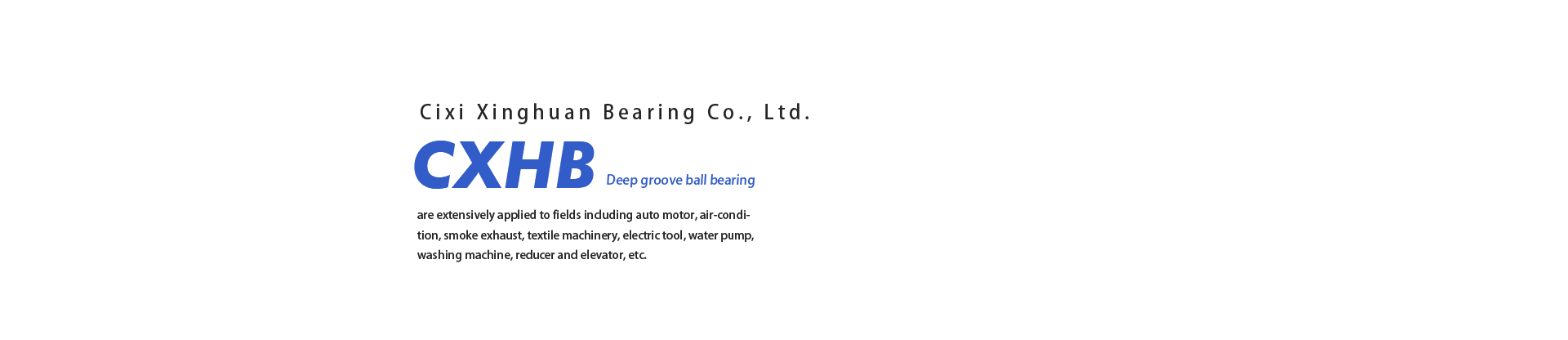

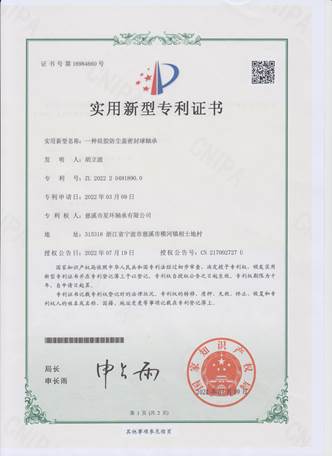

The role of high quality tooling and abrasive materials in production is sufficient to compete with instruments and equipment. In order to purchase these critical materials, we set our sight on the globe, search and select high quality materials around the world, making our product quality reach world standard.